Power Conditioners

Two-in-One for Voltage and Spike Correction

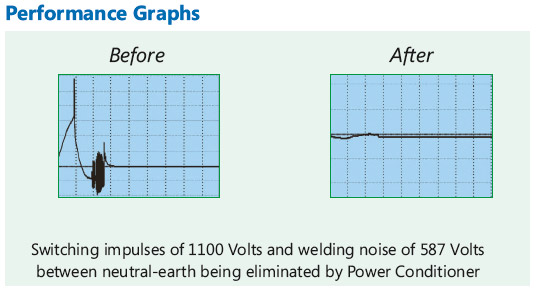

Large amount of CNC breakdowns are attributed to fluctuations in voltage and various types of electrical noises like spikes, surges, high frequency noises, ground noise, etc.

Electrical noises are generated due to switching action of breakers, heavy machinery, capacitor switching, induction hardening, cranes, welding etc. The use of invertors, DC drives, SMPS, while necessary, also further pollutes the electrical environment and cause severe power quality disturbances to various CNC machines which demand stringent standards of power quality for their smooth and trouble-free operation.

Effects of Electrical Noise

Occurring over a wide band of frequency ranging from 1KHz to 100 MHz or more, in magnitudes as high as 4000-6000 Volts on 3 Phase supply systems.

High frequency noise can interfere with digital electronic equipment and cause untraceable data errors, change of programme, memory loss and erratic machine behaviour.

High voltage spikes can cause the failure of Thyristors,Transistors, Microprocessors, etc.

Powercon's Dual Action ensures Clean and Steady power supply

Unity's Powercon works as a dual action protector by simultaneously eliminating major electrical disturbances and voltage fluctuations, providing isolated power for various advanced machinery. Powercon works fast to prevent fluctuations and reduces equipment breakdown for continuous smooth operations.

Key Features

Instant Response & Fast Corrections

Variable speed Servo motor and proportional control circuits provide a response time of 10msec to correct voltage fluctuations without noise or oscillations in output.

Lower Running Cost

Due to high operation efficiency of better than 98% as compared to 95% from other brands.

Total Protection

Shields electronic equipments that produce different types of electrical noise, typically CNC Machines, Drives, Hardening machines and Telecommunication equipment

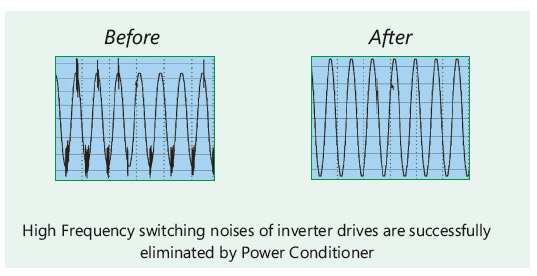

Noise Elimination

Prevents damage due to circulating noise interference within electronic equipments.

Digital Metering System

Data logger with LCD/LED display screen provides detailed information about various electrical parameters to help monitor power quality.

Handles Frequent Start-Stop Cycles

High overload capabilities allows frequent starting and regenerative currents as required by CNC machines and D.G. Sets, among others.

Stringent Quality Standards

Use of high grade materials and advanced engineering design principles ensure greater reliability and consistent performance. Approved by defence and international certification agencies

Technical Specifications

| Ratings | 10, 15, 20, 25, 30, 40, 50, 60, 75, 85, 100, 125 KVA |

| Input Voltage* | 340 - 480 V AC / 360 - 460 V AC / 300 - 480 V AC |

| Phase | 3 Phase, 4 Wire |

| Frequency | 50 Hz |

| Output Voltage* | 200 V AC / 380 V AC / 415 V AC |

| Regulation | ± 1% |

| Rate of Correction | Up to 105 V/sec |

| Common Mode Noise Rejection | 100 dB |

| Normal Mode Noise Rejection | 40 dB |

| Metering | Voltage, Current, Frequency |

| Protections | Under & Over Voltage |

| Overload & Short Circuit Single phasing / Phase reversal+ Surge suppression+ Ground leakage monitoring+ |

|

| Cooling | Air Cooled |

| Ambient | 0 - 45 °C, RH upto 90% |

| Enclosure | Sheet metal, epoxy powder coated RAL 7032 |

| *Non standard voltages are also available. +Optional |